PLM for Apparel Industry is a Strategic Imperative to Remain Competitive

Last month, trade magazine Apparel published its ninth annual report on PLM for apparel industry and the benefits of using PLM technology. Produced in collaboration with IT research firm Gartner, Inc. and based on data from their annual surveys of apparel retailers and manufacturers, these reports offer tremendous insight into the proven benefits of PLM for apparel industry.

As reported in the June 2014 issue of Apparel, this year’s survey reveals the following about the impact of PLM in apparel manufacturers:

- 38% have reduced product development time

- 19% have improved overall margin

- 29% have reduced total lead time

- 24% have achieved faster time to market

- 29% have reduced inventory

- 14% have seen other improvements to the bottom line

The 2014 survey also indicates that 50% of apparel companies plan to make further investments in PLM. Of that group, 78% intend to act within the next 6-18 months.

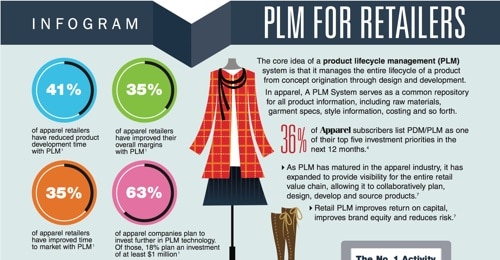

Further evidence of the growing use of PLM by apparel companies is depicted in the compelling infogram “PLM for Retailers”, posted earlier this year by manufacturing technology solutions provider PTC.

In addition to retailer-specific data, PTC’s infogram also presents the following statistics for the apparel industry’s retail and manufacturing companies:

- 45% of apparel companies have already implemented PLM

- 18% of apparel companies plan to implement PLM by mid-2015

- Among those planning to implement PLM, 43% expect to purchase a packaged application from a software vendor.

Why is PLM a competitive necessity in today’s apparel manufacturing industry? The answer comes from understanding PLM’s capabilities and its potential impact on your business:

- PLM facilitates efficient collaboration among all stakeholders through all phases of product design and development, leading to faster product cycle times and reduced time to market.

- PLM provides a single, shared source of product data, enabling real-time updates and eliminating communication lags, data inconsistencies, and the need for data duplication and distribution.

- PLM manages the requirements for domestic and international regulatory compliance, ensuring that products and manufacturing processes meet or exceed increasingly complex guidelines for product safety, worker protection, environmental safeguards, etc.

- PLM increases the visibility of product development cost components and resource allocations, enabling management to make adjustments and reduce costs as needed.

- PLM provides automated and fully-integrated support for:

- Seasonal calendar management

- Product ideation and design

- Merchandising and line planning

- Color definition

- Materials designation and testing

- Product specification management and change tracking

- Sample management

- Supply chain management

- Product sourcing

- Cost modeling

- Quality control

When considered together, PLM’s tangible benefits and growing user base should serve as a wake-up call for the 55% of apparel manufacturers who have not yet implemented an automated PLM solution!

If your business is ready for PLM, we recommend that you utilize a PLM software package tailored to the needs of apparel manufacturers and work with an experienced PLM specialist to define functional requirements, configure your customized system, and train users.

For additional information on how Zweave assists companies in the apparel industry with all aspects of PLM system implementation, please download our whitepaper “15 Reasons to Choose Zweave for Your PLM Project”.